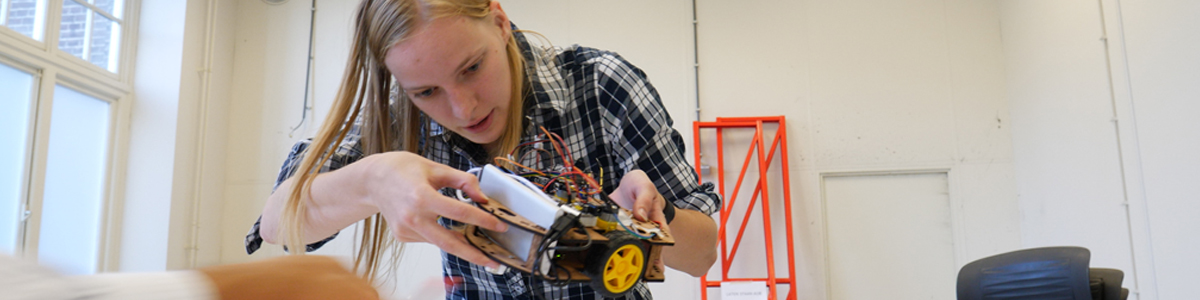

How can robots learn to move and act in a people environment? And what skills should a robot engineer have to make a good contribution to industry and society? These two questions were central in setting up the new Master’s degree programme in Robotics at TU Delft. The answer is clear: the robot engineer is a key figure at a business, and must be able to integrate multiple disciplines with each other and oversee various processes within a development system. Students on the new Master’s degree programme in Robotics at TU Delft therefore develop a wide range of skills at the intersection of mechanical engineering, artificial intelligence, systems integration, business administration and personal development, alongside the ‘normal’ technical skills.

Co-creation between TU Delft and industry

The new Master’s degree programme in Robotics is the result of a dynamic process in which researchers and students from TU Delft worked closely together with the business community. From various perspectives, a clear professional profile was created with a description of the context in which the robot engineer operates, the skills needed to do so, and how the programme content can line up with this.

After completing the programme, Master’s students must be able to connect various disciplines, such as software development and mechanics. In a multidisciplinary team, they maintain an overview of an entire development system. The students therefore also work on skills such as showing a self-critical and learning attitude, presenting their research and giving and receiving feedback. They keep a record of all their learning experiences in a portfolio, in which context they have to be constantly aware of their own role in a project team.

“It was quite a journey setting up this master. I am particularly proud of the fact that, together with the business community and lecturers, I have succeeded in creating an exciting, broad curriculum. The quality and flexibility of the programme and the many moments of reflection that we have built in ensure that, as new robotics engineers, we can respond well to the needs of industry and society.” – Joram van der Sluis, Master’s student in Vehicle Engineering

“Developments within digitisation are moving at lightning speed. We are therefore eagerly looking for engineers who can guide and supervise the transition to further robotisation. I am very happy with the curriculum of the new Master’s degree programme in robotics at TU Delft. This is the type of engineer I’m looking for. These new Master’s students learn and work in a system-oriented way and know a lot about mechanics as well as, for example, software development, systems and control and machine perception. He operates as the ‘homo universalis’ in a multidisciplinary team. The robot engineer of the future cannot afford to be only good in one area. In order to make a difference, the engineer must be strong in communication and be able to master multiple fields.” Arjen Mateboer, Head of Mechanical Engineering R&D Lely, robots for dairy farmers

The Master’s degree programme in Robotics

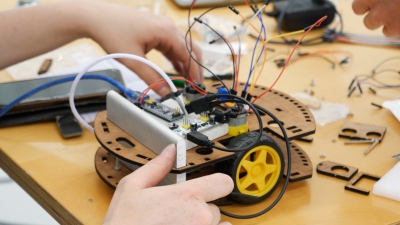

The Master’s degree programme in Robotics is dedicated to the development of the intelligent robot that perceives the environment, makes plans and decisions, and controls itself or moves around in a complex environment in which people may be located. The technical core subjects in the course are dynamics and control, machine learning, robot software practicals, machine perception, planning & decision making, human robot interaction, and a multidisciplinary project. The second year is dedicated to a Joint Interdisciplinary Project (JIP) or internship and graduation. The programme focuses on, among other things, the agricultural, automotive, logistics and production sectors.

Master coordinator and senior lecturer Joost de Winter explains: “The industry is increasingly seeing the importance of robotics research. Delft engineers manage robotics solutions that enable a company to innovate its technologies. Collaboration with industrial partners also leads to interesting new research. A win-win situation as far as I’m concerned.”