Pieter Smakman started Manometric in 2017, a company that makes custom-made orthotic braces using a unique 3D scan and print technology method. Smakman and co-founder Robin Jones developed the start-up to into a successful company that now employs 21 people. And it’s the employees who make it work, according to Smakman. “I believe that the only sustainable way to ensure that a company remains scalable is to employ people who are at the top of their game and of which the majority shows leadership qualities as well. I don’t believe in shortcuts.”

The concept

“I graduated from TU Delft in 2015 with a project on a 3D scanner for hands. It happened quite by chance, I had seen a graduation project for a foot scanner with Professor Molenbroek, but the opportunity had already gone. He said: ‘Why don’t you make a hand scanner instead?’ No sooner said than done. As well as being an extremely interesting case, it also revealed a gap in the market.”

Riding the wave

“Starting a new company is a bit like surfing. You lie there in the sea, waiting for a huge wave to come along. I saw a few waves, like virtual reality and the internet of things, but 3D scanning and printing was also an emerging industry that grabbed my attention. Robin and I were both particularly interested in healthcare. I think the greatest disruptions in the coming years will be in that sector, and that’s really needed. We wanted to ride that particular wave, in combination with the fascinating technology of 3D printing. All these aspects come together at Manometric.”

The first idea is never right

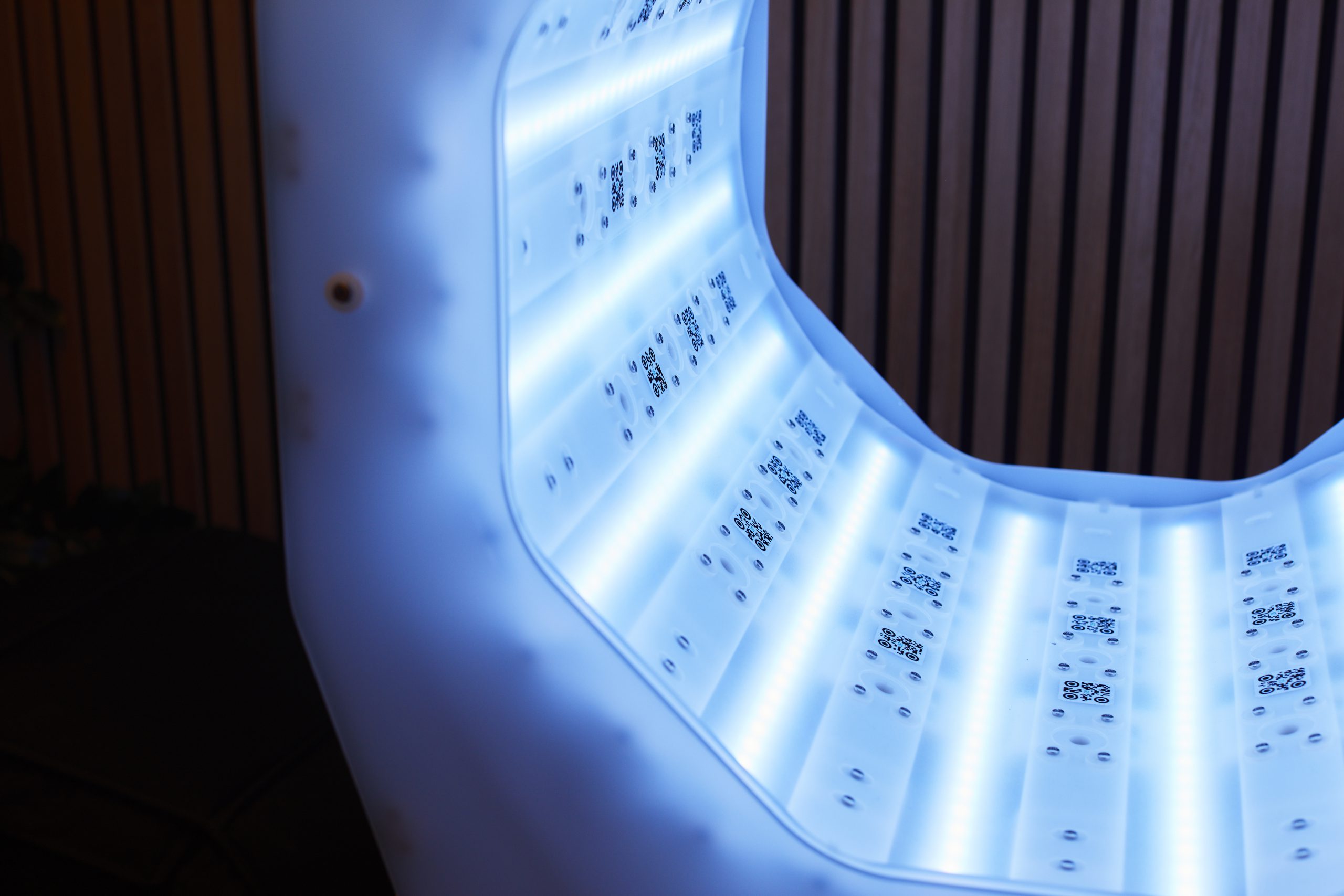

“Our initial idea was to make custom-made surgical instruments. Surgeons sometimes have to operate for six hours at a stretch and as the instruments they use are one size fits all, they soon get painful hands. So we thought about producing custom-made instruments. Once we started talking to doctors, the idea of making orthotic braces, which are also custom-made products, started to take shape. For people with chronic hand problems who were the brace on a daily basis, it is important that it fits perfectly. Our braces are personalized, we make a scan of every patients hand. That only takes a few seconds, a huge timesaver compared to traditional plaster. So, we changed our application. My first idea is never right. I threw away everything I had thought up in theory, and realised that we needed personal and practical experience to come up with a good product.”

‘A hundred applications within two days’

“Our first brace didn’t look good and fell apart as soon as you looked at it, quite hard to look at for us as designers. Even so, YES!Delft encouraged us to organise a demo day. Otherwise you could spend years working on a product that the market doesn’t want. We posted advertisements on Facebook inviting people to come and buy a brace for one hundred euros, and we had a hundred requests from all around the Netherlands within the first two days! All these people came to Delft on a Saturday morning for a scan and a brace. That’s when I knew we were on the right track. If there’s so much consumer demand for a product, and so much dissatisfaction with the status quo, there must be room for innovation.

Now, the brace has a beautiful design as well. We want to be the Apple of the orthopaedic industry.”

Complement each other

“Robin (co-founder) and I have known each other since we were three years old. We know each other through and through, and recognise each other’s strengths and weaknesses. He is meticulous and obliging, more modest than I am. Robin makes sure that everything runs smoothly, and that the contracts with the healthcare insurers are in order. I’m more extrovert towards the team and our clients. We complement each other nicely.”

Investing in talent

“Robin and I aim to make something that is good from the start. The company isn’t producing cheap meat, where rapid growth is more important than quality. That’s why recruiting the right talent is our top priority. We won’t settle for anything less than dream candidates. I truly believe that the only sustainable way to make your company scalable is to get the right people to commit to you. To me, a company is simply the sum total of the great employees who work there and share a point of view.”

Talented employees can learn so much at scale-up companies

“A lot of new graduates look for jobs in consultancy or major companies. I think it would be much better for them to work in an organisation that makes its own products and where they are in touch with the end users, in our case the patients. After all, that’s why you do it. I think that a scale-up company offers more opportunity for personal development. People who are interested in entrepreneurship often assume that they must found their own start-up company. But why not work for a fast-growing company, a company with a promising product? It’s just as exciting in terms of entrepreneurship, and certainly no less interesting.”

Moving away from YES!Delft

“You learn so much from each other here. The real strength of YES!Delft is that you are all working together in one building. It’s easy to stay in contact with other companies if you see them every day at the coffee machine. We’ve grown out of the place, we’ve got six rooms now, spread around the building. We’re moving to a beautiful location in The Hague at the end of the month. It’s still close by and easy to reach for the students who we are keen to offer internships.”